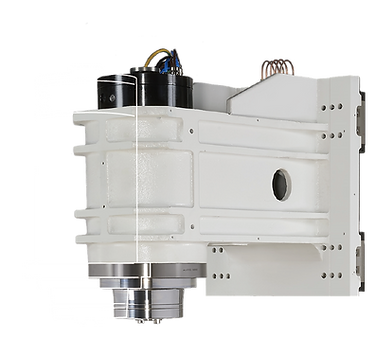

BUILT-IN

SPINDLE

15,000 ~ 18,000 / 20,000 rpm Speed

41 HP / 47 HP* Power

104 ft-lb / 88 ft-lb* Torque

2,645 lbf Clamping Force

1.5 sec Acc. 0 – 12K

1.8 sec Dec. 12K – 0

High Power

High Speed

High Precision

Heavy Cut

SPECIFICATIONS

Spindle speed

15,000 RPM

15,000 rpm Speed

31 kW (41 HP) Power

141 Nm (104 ft-lb) Torque

1,200 kgf (2,645 ft-lb) Clamping Force

1.5 sec Acc. 0 ~ 12K

1.8 sec Dec. 12K ~ 0

18,000 RPM

18,000 rpm Speed

31 kW (41 HP) Power

141 Nm (104 ft-lb) Torque

1,200 kgf (2,645 ft-lb) Clamping Force

1.5 sec Acc. 0 ~ 12K

1.8 sec Dec. 12K ~ 0

20,000 RPM

20,000 RPM

20,000 rpm Speed

35 kW (47 HP) Power

119 Nm (88 ft-lb) Torque

1,200 kgf (2,645 ft-lb) Clamping Force

1.5 sec Acc. 0 ~ 12K

1.8 sec Dec. 12K ~ 0

Standard equipment

*Optional equipment

*Optional equipment

■ Powerful integrated 40 taper dual contact spindle.

■ Maintenance free 15,000 ~ 18,000 rpm spindle requires no added oil or grease.

■ Micro Dynamics drawbar has been rigorously tested to sustain more than 2 million cycles.

■ For all applications, from heavy duty to high speed machining.

■ Highest productivity under any conditions and complexities.

■ CTS (Coolant Through Spindle) designed to sustain up to 100 bar (1,500 psi).*

PERFORMANCE

Power Characteristics

40 Taper Dual Contact

15,000 ~ 18,000 rpm Spindle

15,000 rpm standard spindle, using two-sided restraint BBT40 spindle, With an output of 31 kW / 141 Nm, 4G SSS G05P20000 high-speed and high-precision cutting mode, The whole machine adopts components imported from Germany and Japan to ensure high stability of operation for many years.

40 Taper Dual Contact

20,000 rpm Spindle

Micro Dynamics optional 20,000 rpm spindle, available on all models, delivers 47 HP of power and 88 ft-lb of torque. This allows for fine finishes while still achieving high material removal rates in a wide range of material types.

MODULAR DESIGN

ATE motor integrated with hybrid ceramic angular contact bearings.

®

All Micro Dynamics spindles are built with all shelf standard bearings which can be replaced without removing the rotor. This makes all machines simple and fast to maintain. Rebuild costs are very low due to the availability of the parts and the short service time.

■ Highest quality components to ensure fast and smooth cutting strategies

MOLD & DIE

Mold Finished Product